Heat exchangers are used to cool hydraulic systems on machine tools, injection molding machines for plastics and rubber, mobile operating machines and industrial installations in general.

They allow the dissipation of excess heat between the oil and the cooling fluid (air or water). The choice between the different models depends on environmental and functional factors.

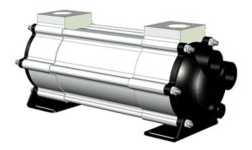

Water-oil heat exchangers

They consist of small diameter tubes inside which the cooling water flows, contained in an external tube (shell) in which the oil flows instead.

They are normally used for the cooling of oil hydraulic systems and are installed on the return line of the system. For the same size they have a significantly higher efficiency than air-oil exchangers.

The well known MS series has recently been replaced by the new MSG series.

Catalogue (PDF)

MSG84 series

MSG134 series

MS84 series

MS134 series

Air-oil heat exchangers

They are used for cooling hydraulic oil and fluid through forced ventilation.

A wide range of cooling devices is available, with alternate current electric motors (AP series), direct current (APL series) and hydraulic motors (AP I series) to meet the different applications and environmental conditions.

Catalogue (PDF)

AP series

APL series

Brazed plates heat exchangers

The brazed plate heat exchanger consists of packed stainless steel plates, in order to generate two separate paths in which the water and the fluid to be cooled flow in opposite directions.

They are avaiable in three different series (M18, M25 and M55), for oil flow rates from 10 to 440 liters / min. The maximum operating pressure is 30 bar.

Catalogue (PDF)

Brazed plates (M18-M25-M55)